Contents... (click to jump to a section)

Introduction

Purified water is widely used within the within the manufacturing, engineering and pharmaceutical industries, across a wide range of applications. Potable water, although safe for human consumption, is not sterile. Mains water contains minerals, such as calcium and magnesium, chemical compounds and microscopic organisms. These pollutants render potable water unsuitable for use within food, pharmaceutical, and healthcare manufacturing industries, where water standards must be maintained to prevent contamination. Impurities in water can also react with delicate microelectronics, or lead to a build-up on product surfaces, impairing performance.

Within industries where production relies on a ready supply of purified water, maintaining the correct levels of purity required is critical to preventing costly downtime, and essential for compliance with FDA, EU and British water standards.

Industrial water purification methods include filtration, deionisation and reverse osmosis, which can be used separately, or in conjunction with each other, to achieve the level of purity required. Purified water can either be purchased in containers, or produced on site using a water purification system.

At Wychwood Water Systems, we specialise in the development, manufacture, installation and maintenance of water purification systems and water treatment technologies. For over 20 years, our experienced team of technicians and engineers have supported hundreds of satisfied customers across a broad spectrum of industries.

Water Purification Systems

Water Purification Systems

Wychwood Water Systems specialise in two main types of in-plant water purification system; reverse osmosis systems (RO) and deionisation (DI) systems. Both methods of purification remove the cost of purchasing delivered containerised treated water, but each has its own specific merits and challenges.

Reverse osmosis is a cost effective, non-chemical water purification method, ideal for removing bacterial and organic contamination. This method is well suited to applications within the pharmaceutical, cosmetic and healthcare industries. However, due to the fact that some contaminants such as chlorine, calcium and magnesium are not removed by reverse osmosis, these must be removed by pre-treating the water before entry into the RO system.

Deionisation is a complex chemical purification process that is extremely efficient at removing mineral and metallic impurities, but ineffective in dealing with organic impurities, bacteria or viruses.

Both reverse osmosis and deionisation can be used as complementary processes; or one may suffice, depending on the purity levels required to comply with safety standards for your industry. Our qualified and experienced chemical engineers can offer advice to help you make an informed choice on the right type of system for your operation.

What Is Reverse Osmosis?

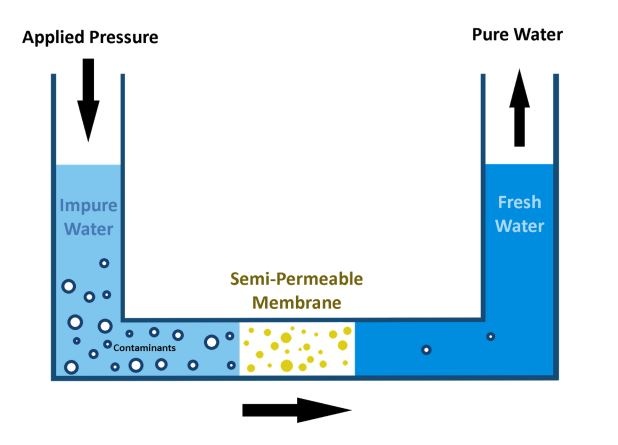

Osmosis is a naturally occurring process, where water molecules move from areas of high water concentration to an area of lower water concentration, passing across a permeable membrane.

Reverse osmosis applies this principle in reverse, using energy to overcome the natural force of osmotic pressure. The water is pushed across a membrane from low water concentrations (impure solution) to high water concentrations (purer solution).

This creates an efficient and chemical free method of water purification. The semi-permeable membrane allows the passage of water molecules, but acts as a barrier to larger contaminant molecules, creating a highly effective filter against dissolved salts, organic compounds, bacteria and pyrogens.

How Commercial Reverse Osmosis Water Purification Systems Work

A reverse osmosis system uses a high-pressure pump to push the water supply in a cross-flow direction across a semi-permeable membrane. High pressure pumps typically vary in size from 1 to 10 kW, depending on the plant capacity. The membrane is made from a flat sheet of thin polyamide film, perforated with tiny pores. The decontaminated water, called permeate, passes through these pores, to an outlet for immediate use or storage. 95% to 99% of dissolved salts and 99% of organic compounds are left behind in the concentrate, which is diverted to a reject stream, for drainage or recycling back through the system.

Purification Performance Vs Water Waste

The percentage of purified permeate water collected is called the recovery percentage. This is an important factor in the design of the system, which can affect the longevity of the membranes and the overall cost effectiveness of the system over its lifespan. The higher the recovery percentage, the lower the amount of waste water sent to the drain outlet.

However, if the recovery rate is too high, the levels of contaminants on the concentrate side of the membrane can lead to bacterial growth, fouling or scaling – all of which can lead to frustrating downtime, while problems are rectified.

A recovery rate of 70% is the ideal standard for maintaining optimum performance and efficiency within most industrial uses, depending on the feed water characteristics and other design considerations.

How Much Water Is Wasted In Reverse Osmosis?

Between 25% and 30% of the feed water will enter the waste stream. This is necessary for both removal of the dissolved contaminants and to flush the surfaces of the membranes to prevent fouling. However, as the discharged water is only slightly less pure than the source water entering the system for treatment, it can be collected for reuse in several further applications; thereby decreasing the level of waste. To reduce waste even further, the concentrate can be collected and used for any domestic, but non-potable use, or process wash-down.

Reverse osmosis systems available on the market typically run at anywhere from 50% to 80% recovery. Any system operating outside of these parameters will be ineffective and costly to operate, and should always be avoided. We also recommend caution when dealing with companies promising over 80% recovery rate. This simply means the membranes are being worked harder and will require more regular replacement.

A reverse osmosis system from Wychwood Water Systems is designed to operate at a 70% recovery rate, to reduce waste and increase the life span of the membranes, and for an increased return on investment.

Industrial Uses Of Reverse Osmosis

Reverse osmosis was originally developed to generate drinking water from sea water. The process is extremely effective in purifying brackish, surface and ground water because there are no harsh chemicals involved in the purification process or waste concentrate. The RO method is also suited for use within the following industrial applications:

- TDS (total dissolved solids) reduction for high pressure steam boilers

- Metal finishing

- Chemical manufacture

- Product testing

- Semi-conductors & electronics

- Glass & lens production

- Pharmaceutical manufacturing

Industrial reverse osmosis systems are effective at removing organic compounds, mineral salts and contaminants such as ethanol. This makes an RO system ideal for use in plants with high levels of total dissolved solids in the feed water.

Limitations

Chlorine, calcium and magnesium cannot be removed by reverse osmosis, along with barium and silica. Reverse osmosis is also less suitable for processing water that contains a high silt content; as silt particles clog the membranes more frequently.

While reverse osmosis removes bacteria and larger viruses, it should not be relied upon to purify the water completely. Industries requiring additional protection should eliminate bacteria by pre-treating the water using heat sanitation or UV sterilisation.

The Vulnerabilities Of Reverse Osmosis Water Purification Systems

While the key advantage of reverse osmosis systems is their ability to remove organic and bacterial impurities without using harsh chemicals, there are also a number of vulnerabilities which must be monitored and managed to prevent bacteria and scale from building up within the system.

Luckily system performance is easy to measure through a daily visual examination of the flows, pressure and conductivity values. This makes it easy to identify potential problems and take preventative action. A professionally installed, quality system suited to the intended purpose, supported by monitoring and maintenance, can overcome almost all vulnerabilities associated with RO systems.

Pre-Treatment Of Feed Water

Pre-treatment of feed water is critical for preventing damage to the membranes of the system.

Calcium and magnesium create scale deposits that can damage the pores of the membrane and create an environment suitable for bacterial growth. Water softeners should be used to remove calcium and magnesium. The softening agents cannot cross the membrane, so are removed from the permeate.

Chlorine degrades the composite material of the membrane, allowing contaminants to breach the membrane, which reduces the recovery rate of the system. All feed water for RO systems must be pre-treated by removing the chlorine with activated carbon.

At Wychwood Water Systems we recommend the following pre-treatment measures:

- Granular Activated Carbon (GAC) installed in an automatic backwashing unit, such as the FILTERMAT unit, to remove free chlorine and organic matter

- Install a generously sized duplex meter pair of controlled release water softeners, sized at <30 BVH, (bed volumes per hour flow to resin media volume ratio)

- A constant softened feed water of < 4ppm hardness to prevent RO membrane scaling

- Quarterly replacement of 5 micron absolute rated depth filters to remove any physical particles greater than 5 microns, and to ensure the feed water fouling index is less than 6

Using the above best practice water treatments will increase the performance of the membranes and minimise maintenance. Alternatively, the system can be fed with water that has already been deionised to achieve the highest purity levels.

Mechanical Damage

The membranes are easily damaged by hydrostatic shock caused by sudden changes to the water pressure. Likewise, too much backpressure can cause mechanical damage to the membranes. There are many variables which can affect the density and pressure of the liquid within the RO system, including temperature, feed pressure and feed flow.

Professional design and installation of the system by an expert is highly recommended to ensure the system incorporates safeguards for preventing hydrostatic shock; such as variable frequency drive motors to start the high-pressure pumps, check valves and pressure relief valves. The feed pumps and pipework should also be of adequate size for the system.

Bacterial Growth

Bacteria is the most common threat to RO systems, as it is present within water. Failure to maintain optimum conditions throughout the system, or to perform regular cleaning and maintenance, can quickly lead to bacterial growth. Should this occur, the system must be shut down and microbiological diagnosis and chemical intervention will be required to overcome the problem.

The following avoidable mistakes can all increase the occurrence of bacterial growth:

- Inadequate water flow – If the flow is insufficient, water can stagnate in areas of the system, creating the ideal environment for bacteria to multiply.

- Failure to pre-treat the feed water – Chlorine decays the surface of the membrane, creating areas of physical damage that form a haven for bacteria to thrive.

- Failure to maintain the correct temperature – Bacteria can fast become a problem in systems operating below 20°C.

- Inadequate Disinfection – Regular routine disinfection of the system, using hydrogen peroxide treatments or heat sanitation are required to ensure continuous operation. Disinfection reduces the overall amount of chemicals required to maintain the system.

Scale & Clogging Of The Membrane

Membranes must be cleaned regularly to remove the accumulation of calcium deposits, silt particles and organic materials. An increase of between 10% and 15% in normalised pressure between feed and concentrate headers can indicate the need for membrane cleaning. Scale can be dissolved by soaking the membranes in permeate water while the system is on standby, to reduce the requirement for chemical scale removal.

The purity of the permeate will soon decrease if regular cleaning and maintenance is neglected. Once fouling occurs, a two-stage cleaning process is required using both low and high pH cleaners to remove mineral deposits and organic compounds.

In a well maintained system the membranes should typically last for three to five years. Regular cleaning reduces downtime and prevents unnecessary replacement costs. The installation of a cleaning in place (CIP) rig is the most effective way to increase the longevity of the membranes, thus increasing your ROI from the system.

The Importance Of Ongoing Maintenance

The foundations of high performance and cost-effective water purification are:

- A well-designed system, suited to the industry standard levels of purity required

- The ability to monitor performance parameters

- Regular ongoing maintenance

Every RO system should be monitored and inspected daily. A quality system should incorporate instrumentation that enables close monitoring of the following parameters:

- Feed pressure

- Permeate pressure

- Concentrate pressure

- Feed conductivity

- Permeate conductivity

- Feed flow

- Permeate flow

- Temperature

Fluctuations in any one of these performance indicators can signify a problem. While many potential issues can be prevented by following good practice, the support of an experienced water purification expert should always be enlisted if the reverse osmosis recovery rate falls below 70%. This is a warning sign that the system is not working correctly.

Swift diagnosis and rectification of the underlying problem can prevent a serious issue from developing. Fast action reduces the downtime and expense. Always choose a supplier who can provide fast, reliable, professional engineer support.

Log Every Inspection

A simple daily record of each inspection will build a detailed history of your system’s operation. This makes it easier for facilities and works managers to plan for future repairs or replacements - helping to budget for costs and providing control.

Reverse Osmosis Systems From Wychwood Water Systems

The LABSTAR reverse osmosis range, from Wychwood Water Systems, provides market leading efficiency and reliability.

LABSTAR Range Features & Benefits

LABSTAR Range Features & Benefits

Our LABSTAR system is a compact, cost effective, chemical free reverse osmosis system ideal for laboratories and manufacturing facilities where small volumes of purified water are required.

- Available in two water flow and two water quality formats

- Permeate output between 30 and 160 litres per hour, highly cost effective for variable production quantities

- Absolute rated pre-filtration, including organic absorption, removes up to 99% of total dissoluble solids (TDS)

- Integral system pump

- The enclosed units can be floor, wall or bench mounted

- Efficient low pressure membranes consume minimal power to reduce energy costs

- Wall mounted illuminated colour change display providing continuous conductivity monitoring

IONMASTER RO

IONMASTER RO

The IONMASTER RO uses the latest thin film composite reverse osmosis membrane technology and user-friendly control systems.

These compact units are available in vertical and horizontal membrane formats to minimise space requirements. Models are available from 30 litres per hour up to 20,000 litres per hour. The membrane performance is a reflection of the latest developments, with 98% to 99% rejection of the feed water total dissolved solids (tds), and 70% of the feed water recovered as purified water.

These performance characteristics make the IONMASTER RO range a very economic solution, when compared with other more conventional water purification processes.

All models in the range have a control system to complement this quality approach. The extensive information and control available to the end user provides ease of performance monitoring.

High Performance Efficiency

Our systems have been specifically developed to reduce operation costs, increase efficiency and assist maintenance. Our systems use low energy XLE thin film composite membranes, capable of handling high flow under lower feed pressures, to reduce energy consumption, while still maintaining high fouling resistance.

Our wall mounted, illuminated colour change display provides continuous conductivity monitoring. When the preferred output conductivity exceeds the pre-set value, the backlight flashes red, alerting you to potential problems.

We except nothing less than 98% to 99% total solids rejection. Each of our systems operates at the optimum 70% water recovery rate, providing exceptional levels of purity, while increasing the longevity of the membranes.

Why Choose Wychwood Water Systems?

As an independent ISO9000 accredited water purification specialist, we place the utmost importance on delivering quality at every stage of the process. Our trained team of chemical engineers are fully equipped to provide advice and expertise on every aspect of water purification. We will always ensure you receive the right technology and support to meet the needs of your facilities.

In addition to our design, installation, setup and training services we also offer range of additional services including refurbishment, calibration and de-commissioning. Our support services include a preventative maintenance package tailored to your individual requirements, as well as 24-hour advice from our helpline. If onsite assistance is needed, our next day engineer support will help get you back on track quickly.

Our guiding philosophy is to provide the very highest value for money in all our services. Our British produced systems and UK based team of engineers provide an unrivalled service that will enable you to increase your productivity, reduce operational risk and give you a better ROI than almost any other system available on the market.

Is Reverse Osmosis Right For You?

Thank you for downloading this guide. By sharing our knowledge, we aim to equip you with all the information you need to gain the highest levels of performance from our systems. If you are still unsure whether the reverse osmosis process could benefit you, our team members are on hand to help. They can not only recommend the right system, but can also answer your questions about any type of water purification system and technology available.

Contact Us

To speak to one of our friendly team members, or to obtain a quotation, please do not hesitate to get in touch by calling 01993 892211.

Subscribe to our blog for regular articles about water purification, technological developments and related issues affecting the industry at http://blog.wychwood-water.com/

We are a specialist independent company involved in water purification and water treatment technologies

We are a specialist independent company involved in water purification and water treatment technologies