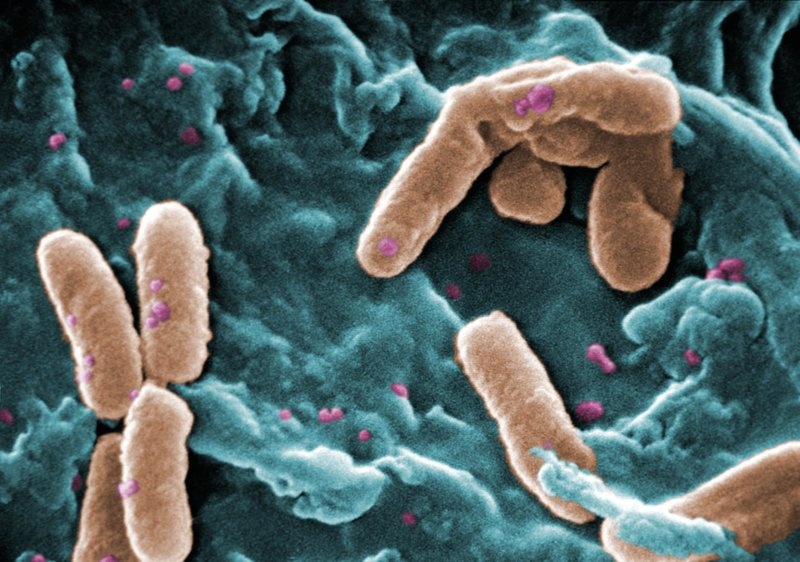

Pseudomonas is a dangerous bacteria which appears in water and soil. While it doesn’t affect healthy adults, it may be deadly for children and people with a weakened immune system. The appearance of such bacteria in the water of production facilities can lead to lethal consequences.

In the UK, Pseudomonas causes over 4,000 infections every year. In 2012, four children died in Belfast and Londonderry hospitals due to contamination of the tap water with pseudomonas bacteria.

Pseudomonas in industrial water purification systems can lead to breakdowns, downtime, and production problems. Thankfully, there are many ways we can prevent pseudomonas in water. All of them require a meticulous approach and careful system monitoring.

Regular Testing

Discovering the presence of Pseudomonas before it forms a biofilm is vital to keeping the system clean and avoiding further contamination. The testing for Pseudomonas is based on its special ability to prevent sugar fermentation.

In order to check for the presence of Pseudomonas bacteria, microbiologists can run an oxidase test. It checks if there is a CO2 gas formation originating in glucose. If the CO2 levels are lower than expected, there is a high probability of the Pseudomonas contamination.

Proper Disinfection

Without regular disinfection, a system can quickly become contaminated with numerous microorganisms, including Pseudomonas. Once the contamination occurs, the whole system has to be shut down until microbiological testing confirms the situation is fully resolved. After extensive assessment, the system must be flushed before put back into service.

Regular disinfection is part of standard water system maintenance. Hiring a team of experts to maintain your industrial water purification system can ensure a proper disinfection procedure and the absence of contaminants.

Membrane Integrity

Pseudomonas in industrial water purification systems often occurs due to the lack of proper membrane maintenance. Reverse Osmosis purification systems depend on membrane integrity.

A clean and strong membrane prevents contamination. However, improper pre-treatment of water or irregular cleaning of the membrane can lead to its fouling and damage. As a result, the membrane stops doing its job, allowing bacteria growth and biofilm formation.

Regular cleaning of the membrane in the reverse osmosis purification systems can help prevent Pseudomonas infection.

System Maintenance

Pseudomonas bacteria can be prevented by maintaining the system properly. For example, the right temperatures should be maintained throughout your pump and pipe network. The pipework joints have to be inspected on a regular basis to avoid the appearance of crevices, where bacteria will happily form.

The water pump should be checked to ensure adequate water velocities slow water delivery without the required turbulence will allow bacteria to grow.

Pseudomonas in industrial water purification systems is a dangerous problem which can be prevented with proper system care. At Wychwood Water Systems, we don’t just help you choose the right system for your needs, we also provide regular maintenance. If you’d like to learn more about our services and bacteria prevention in the purification systems, please download our Industrial Water Purification Guide e-book today.

We are a specialist independent company involved in water purification and water treatment technologies

We are a specialist independent company involved in water purification and water treatment technologies