If you run any kind of water-driven or cooled industrial system, you'll need to be aware of the risk of your machine becoming infected with waterborne contaminants. At Wychwood Water, we offer both filtration and preventative treatment solutions to stop this happening.

Topics: Industrial Water Treatment, Water Purification Solutions

Endotoxin contamination can be a serious problem for manufacturing facilities, especially with processes relating to pharmaceutical, cosmetic and food and drink production. A water purification system should be equipped to test for and deal with endotoxin contamination before they reach unsafe concentrations in the feed water.

Topics: Industrial Water Treatment

Containerised water treatment plants have a big role in water purification and offer one of the best methods available in the market for purifying manufacturing water on demand.

Topics: Industrial Water Treatment

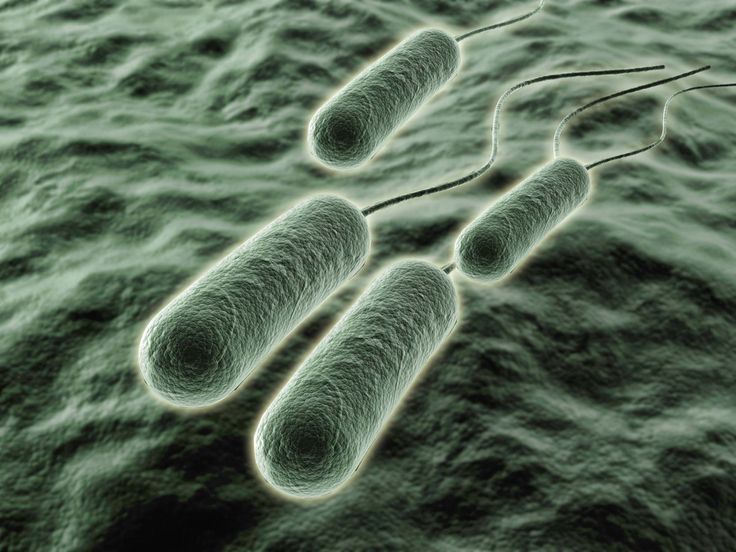

Pseudomonas is a family of 191 strains of aerobic, gram-negative bacteria containing various harmful plant and animal pathogens. Pseudomonas is an adaptable, hardy bacteria that thrives in a range of environments, quickly taking hold in water tanks, food storage and preparation areas and water processing facilities. Once a pseudomonas contamination takes hold it produces a thick fluorescent green/yellow biofilm, which can be very difficult to remove. The biofilm is composed of siderophores, a strong, water-soluble iron-chelating compound that binds to other metallic compounds in the feed water.

Topics: Industrial Water Treatment

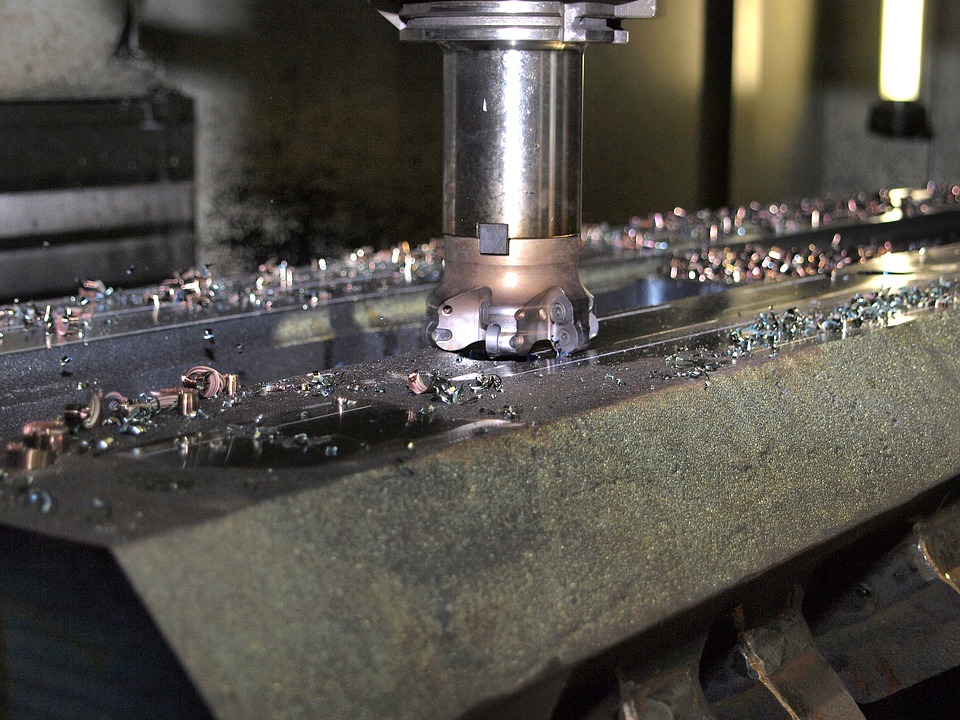

Water Treatment To Improve The Quality Of CNC Machine Coolant

Water used as coolant in CNC machines benefits from treatment to remove chlorine, dissolved gasses and inorganic mineral contaminations. A typical coolant contains 10% refrigerants and 90% diluting water. Water taken directly from the mains or a natural water source contains a variety of compounds ranging from sand and stone sediment to agricultural run-off and microorganisms. The composition of mains water varies from place to place and even at different times of the year, so it is important to know exactly what is going into your coolant water before you use it in a machine.

Topics: Industrial Water Treatment

4 Reasons To Upgrade Your Industrial Water Treatment Systems

Water treatment systems are an important investment and not a purchase decision to be taken lightly. Planned preventative maintenance and routine servicing can extend the life of your system and help you avoid major problems, but there comes a time when this is no longer sufficient. When a system starts costing you more to sustain than the difference in price for investing in a new system, an upgrade suddenly becomes the most cost-effective course of action. Here are some common signs that you should start assessing the capacity of your current plant and consider shopping around for a new system.

Topics: Industrial Water Treatment

3 Principles Of Industrial Water Treatment You Need To Know To Maintain High Water Quality

Industrial water treatment is crucial for every process in a manufacturing facility, from cooling and cleaning to rinsing and processing. When water purity cannot be maintained, products and the equipment used to manufacture them can suffer, leading to costly downtime and even costlier equipment repair or replacement.

In order to avoid the premature replacement of components or equipment, it’s essential to understand the following principles of industrial water treatment.

Topics: Industrial Water Treatment

Here’s Why You Need To Get Your RO Membrane Cleaning Right

Cleaning and maintenance can be a vital part of having an RO water treatment system in your facility. Membranes can become fouled by several contaminants including algae, viruses, fungi and bacteria. If left untreated, these contaminants can affect the entire system, forcing a complete shut-down that can significantly impact your operation.

It's worth pointing out that whilst there many RO’s that need cleaning and cleaning regularly, there are many RO units that operate without ever being cleaned. It’s all down to the quality of the feed water and the quality of the pre treatment - for more information go to http://www.wychwood-water.com/process/reverse-osmosis/.

Topics: Industrial Water Treatment

Tips For Choosing A Water Purification And Treatment System For The Cosmetics And Toiletries Industry

The type of water purification and treatment system you will need for your cosmetics business will depend on the products you are manufacturing, as well as the size of your operation. Ultimately, however, you will need to choose a system that will allow you to adhere to British and European Pharmacopeia standards for water purification.

Generally speaking, the water purification and treatment system you choose for your cosmetics business will be one that produces water with little to no impurities like nitrates, chlorides, heavy metals and sulphates. Any system used to purify manufacturing water must avoid areas where stagnation might be a risk, as this can lead to the proliferation of bacteria.

Topics: Industrial Water Treatment

Threats To Your Industrial Water Treatment System You Weren’t Aware Of

Meeting the BP, EP and FDA standards for the water used in your facility can seem fairly straightforward. However, there are many dangers lurking in and around your system that may be threatening the quality of your water, as well as the efficiency of your water system itself.

We are a specialist independent company involved in water purification and water treatment technologies

We are a specialist independent company involved in water purification and water treatment technologies