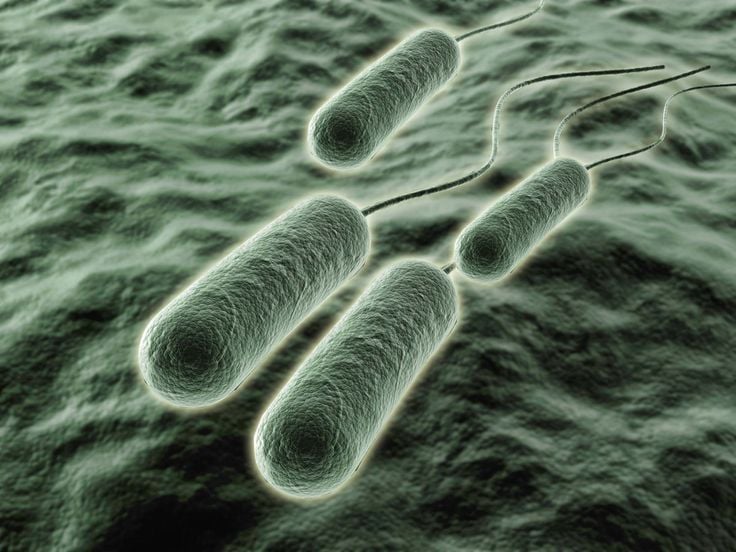

Pseudomonas is a family of 191 strains of aerobic, gram-negative bacteria containing various harmful plant and animal pathogens. Pseudomonas is an adaptable, hardy bacteria that thrives in a range of environments, quickly taking hold in water tanks, food storage and preparation areas and water processing facilities. Once a pseudomonas contamination takes hold it produces a thick fluorescent green/yellow biofilm, which can be very difficult to remove. The biofilm is composed of siderophores, a strong, water-soluble iron-chelating compound that binds to other metallic compounds in the feed water.

Due to the harmful effects on human health and the ecosystem, which will be explained briefly below, it is extremely important that regular tests are taken to detect Pseudomonas in commercial water systems; and treatment procedures put in place to limit its growth.

Food packaging and preparation businesses and scientific establishments are especially susceptible to Pseudomonas contamination.

Risks Associated With Pseudomonas

Pseudomonas is associated with several diseases in humans, plants and animals.

Humans & Animals: The Pseudomonas strain P. aeruginosa is responsible for some of the most common hospital-acquired infections. Many hospitals and clinics have a persistent problem with Pseudomonas. Symptoms, caused by proteins secreted by the bacteria, include pneumonia, blood poisoning and urinary infections. P. aeruginosa is highly contagious and has proven to be resistant to or difficult to treat with antibiotics. Some strains of Pseudomonas are known to attack white blood cells in a range of mammal species, including humans, cattle, sheep and dogs.

Fish: While P. aeruginosa appears to be a specifically human pathogen, P. plecoglossicida affects fish by causing gastric swelling and haemorrhaging.

Plants & Fungi: A number of Pseudomonas strains are pathogenic to plants. The P. syringae family are connected with diseases in a range of agricultural plants, with different strains adapted to specific hosts. A virulent form of the bacteria, P. tolaasii, causes blight and degradation in edible mushroom species, with the potential to cause significant commercial damage for agricultural businesses.

Testing For Pseudomonas

Fortunately, the presence of Pseudomonas can be detected long before the characteristic biofilm and ‘fruity’ odour become apparent. It can be positively detected using the oxidase test, which tests for CO2 gas formation levels originating in glucose. Pseudomonas oxidises glucose compounds, inhibiting fermentation of the sugar. Lower than expected CO2 levels could therefore indicate a growing population of Pseudomonas bacteria.

Treating Pseudomonas Contamination

Pseudomonas thrive in low-temperature conditions, so maintaining a consistent feed water temperature of 20°C or more is a good way to discourage contamination. Pseudomonas contamination can effectively be treated by flushing out your treatment system with a disinfectant solution: although this will involve downtime during treatment, and for testing before and after.

Residual levels of Pseudomonas can be treated on an ongoing basis through Ultra Violet sterilisation. Contaminated feed water can also be treated with one of several bacteriophages, which are species-specific and infect and destroy Pseudomonas bacteria. A specific test must be carried out to determine the strain(s) of Pseudomonas that need to be dealt with, so the right bacteriophage is applied. After treatment, the bacteriophage organisms must themselves be removed through ultrafiltration and UV sterilisation.

Positive Uses Of Pseudomonas

At the risk of giving Pseudomonas an entirely bad name, it does have some positive uses. Pseudomonas is widely used as a bioremediation agent to metabolise waterborne chemical pollutants, including cyanide and aromatic organic compounds. In nature Pseudomonas is believed to play a vital role in the formation of ice crystals and rain in the lower atmosphere.

Our FREE Guide To Commercial Water Purification Systems

Bacterial infections present a significant problem to manufacturing businesses in all sectors. However, with the right equipment and water treatment regime in place, bacterial levels can be controlled and widespread contamination avoided.

Different purification systems are better equipped to keep water free from bacteria than others. To help you make the right choice for your commercial facility, take a look at our Guide To Industrial Water Purification Systems, which can be downloaded for free by clicking here. In the guide we discuss how different filtration and purification systems are used in manufacturing businesses, how to lower maintenance and running costs, and how to minimise the risk of serious issues such as bacterial contamination. For any other questions, please don’t hesitate to get in touch with our team by phone or email.

We are a specialist independent company involved in water purification and water treatment technologies

We are a specialist independent company involved in water purification and water treatment technologies