The deionisation process is ideal for your facility if you need to be able to remove minerals from the industrial water you use. This versatile method of purifying water allows you to achieve pure industrial water in more than one way. It all depends on the products your facility produces.

Peter Wood

Recent Posts

Ways To Achieve Pure Industrial Water Through A DI System

Topics: Deionisation, Deionised Water System

The IONMASTER HMR Selective Ion Exchange System by Wychwood Water Systems

The IONMASTER HMR system is a cost-effective selective deionisation unit that actively removes heavy metals in a variety of applications. Waste water created from metal working and electroplating contains heavy metals which have to be removed using the proper equipment. Quality standards can be maintained by regulating the amount of dissolved solids and heavy metals in water with Wychwood’s HMR unit.

Topics: Deionised Water System

Why Reverse Osmosis Water Treatment Systems Fail And How To Ensure Yours Doesn't

Reverse osmosis systems are used in many facilities that need a non-chemical means of purifying their water. These efficient systems employ semi-permeable membranes to filter out contaminants. RO systems can also remove organic contaminants and bacteria, as well as larger-sized viruses, thanks to the physical barrier the membrane provides.

However, just like any other system, reverse osmosis water treatment systems can and do fail. The failure of an RO system can occur for a number of reasons, but each type of failure is completely preventable.

Topics: Reverse Osmosis

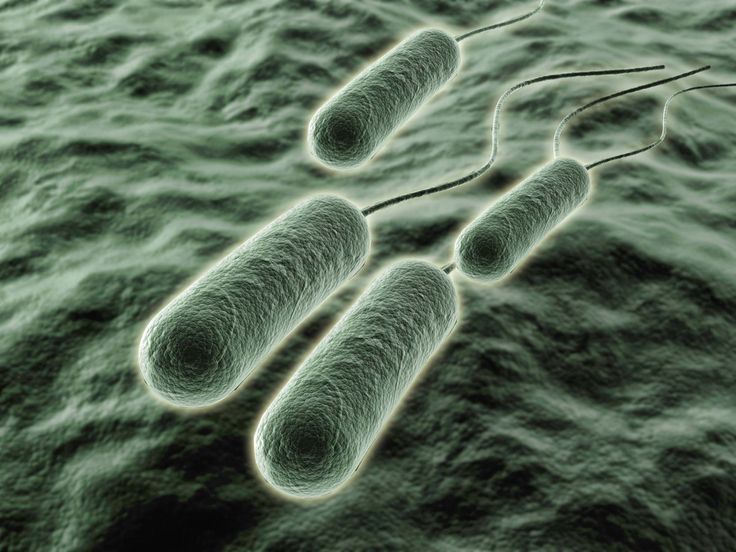

How To Ensure Bacteria-Free Water With An Industrial DI System

Bacteria is a perpetual threat to industrial water purification systems, because all systems offer any number of locations and conditions to promote bacterial growth. Facilities managers must always ensure their staff are on the lookout for signs of bacterial contamination, as not doing so can result in expensive downtime while cleaning and disinfection takes place.

Topics: Deionisation, Deionised Water System

As a category, heavy metals encompass 56 naturally occurring elements stratified by atomic weight. Weight and density vary, with the lightest of the heavy metals sometimes considered to be calcium (atomic weight 20), scandium (40), or mercury (200). Many, such as iridium, nickel, selenium and chromium, are commercially mined. An additional 34 heavy metals, all radioactive and more or less unstable, are produced by transmutation in a laboratory. These include radium, polonium and flerovium. Some heavy metals are fairly innocuous to human health, some harmful in high quantities and others are toxic in even trace quantities.

Topics: Water Purification Solutions

Pseudomonas is a family of 191 strains of aerobic, gram-negative bacteria containing various harmful plant and animal pathogens. Pseudomonas is an adaptable, hardy bacteria that thrives in a range of environments, quickly taking hold in water tanks, food storage and preparation areas and water processing facilities. Once a pseudomonas contamination takes hold it produces a thick fluorescent green/yellow biofilm, which can be very difficult to remove. The biofilm is composed of siderophores, a strong, water-soluble iron-chelating compound that binds to other metallic compounds in the feed water.

Topics: Industrial Water Treatment

Water Treatment To Improve The Quality Of CNC Machine Coolant

Water used as coolant in CNC machines benefits from treatment to remove chlorine, dissolved gasses and inorganic mineral contaminations. A typical coolant contains 10% refrigerants and 90% diluting water. Water taken directly from the mains or a natural water source contains a variety of compounds ranging from sand and stone sediment to agricultural run-off and microorganisms. The composition of mains water varies from place to place and even at different times of the year, so it is important to know exactly what is going into your coolant water before you use it in a machine.

Topics: Industrial Water Treatment

4 Reasons To Upgrade Your Industrial Water Treatment Systems

Water treatment systems are an important investment and not a purchase decision to be taken lightly. Planned preventative maintenance and routine servicing can extend the life of your system and help you avoid major problems, but there comes a time when this is no longer sufficient. When a system starts costing you more to sustain than the difference in price for investing in a new system, an upgrade suddenly becomes the most cost-effective course of action. Here are some common signs that you should start assessing the capacity of your current plant and consider shopping around for a new system.

Topics: Industrial Water Treatment

The Benefits Of Quality Servicing And Calibration For Your Purified Water Systems

Most users who have a new purified water system installed become very reliant on them overnight. It is therefore very important that they are maintained to the highest standard to achieve the best reliability and performance.

Efficient And Reliable Operation

Quality servicing will ensure that the purified water system is set up correctly making the best use of any chemicals or consumable items involved. This approach will also ensure that the minimum amount of waste water is generated and passed to drain.

Topics: Purified Water Systems

Purified Water Systems — When To Repair And When To Replace

Replacing a purified water system is a big capital investment - but there are also significant costs associated with trying to keep outdated, obselete systems going longer than their natural lifespan. So how do you know when it's time to replace your purified water system, rather than just repair it?

Let's consider some of the key factors that will affect your decision:

Life Span

The life span of purified water systems is variable depending on the industry involved and the standards required. A reasonable life span of a system is 15 years. However, there are plenty of 25+ year old systems in operation.

Topics: Purified Water Systems

We are a specialist independent company involved in water purification and water treatment technologies

We are a specialist independent company involved in water purification and water treatment technologies