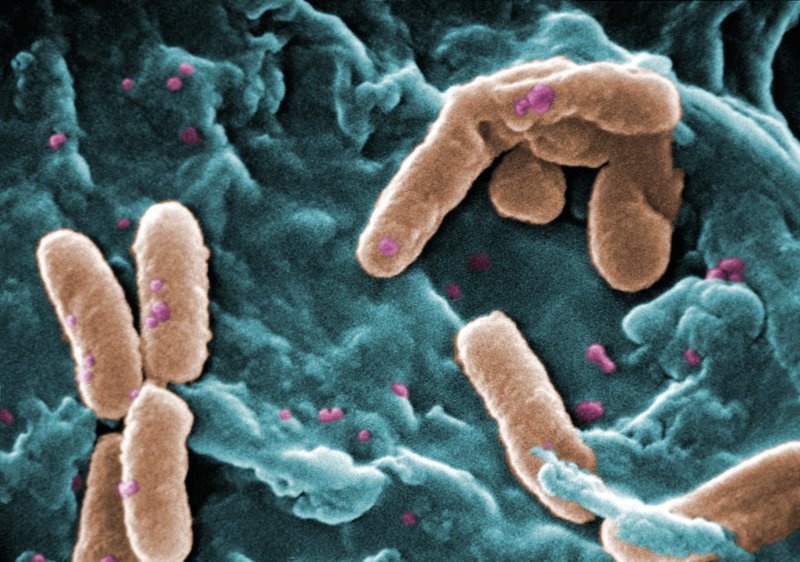

It is crucial for manufacturers to maintain the proper quality of water for their purposes and sector requirements. It is not enough to install the best water purification systems if there are no proper systems in place to keep the system free of bacteria. Pre-treatment devices and the reverse osmosis (RO) system are the systems most at risk from contamination, so require regular testing, cleaning and maintenance to prevent bacterial build-up.

Wychwood Water Systems has supplied and installed several water purification systems used in the chemical industry over many years.

Topics: Deionisation, Purified Water Systems, Water Purification Solutions, Commercial RO System, Continuous Electro Deioniser

How To Prevent Pseudomonas Contamination In Industrial Water Purification Systems

Pseudomonas is a dangerous bacteria which appears in water and soil. While it doesn’t affect healthy adults, it may be deadly for children and people with a weakened immune system. The appearance of such bacteria in the water of production facilities can lead to lethal consequences.

Topics: Purified Water Systems

One advantage of being a small company with experienced technical sales & service personnel is that each enquiry can be considered on its own merits in detail. On this basis after being called in to conduct a review, Wychwood Water carried out a free site survey together with a report on the existing laboratory water purification ringmain system. The existing water purification system had been installed by a competitor and the client was concerned about its longevity.

Topics: Purified Water Systems

Distilled spirits and beers have one common ingredient – water.

Sounds great. Readily available out of the tap, potable, drinkable - job done.

Unfortunately, with the composition of water being variable, and supplies differing geographically, as well as daily, this amazing product isn’t as straightforward as it seems…

Topics: Purified Water Systems

Process water is used in many commercial businesses, often in very high volumes. As it is used, process water often picks up impurities and contaminants that need to be stripped out before the wastewater can be released back into the water network. This is expensive for the businesses concerned, as well as being extremely wasteful. Thus, facilities that use large amounts of process water frequently benefit from employing techniques that can conserve and recycle process water for further use. This not only makes sound environmental sense, but can also save businesses a lot of money.

Topics: Purified Water Systems

The Benefits Of Quality Servicing And Calibration For Your Purified Water Systems

Most users who have a new purified water system installed become very reliant on them overnight. It is therefore very important that they are maintained to the highest standard to achieve the best reliability and performance.

Efficient And Reliable Operation

Quality servicing will ensure that the purified water system is set up correctly making the best use of any chemicals or consumable items involved. This approach will also ensure that the minimum amount of waste water is generated and passed to drain.

Topics: Purified Water Systems

Purified Water Systems — When To Repair And When To Replace

Replacing a purified water system is a big capital investment - but there are also significant costs associated with trying to keep outdated, obselete systems going longer than their natural lifespan. So how do you know when it's time to replace your purified water system, rather than just repair it?

Let's consider some of the key factors that will affect your decision:

Life Span

The life span of purified water systems is variable depending on the industry involved and the standards required. A reasonable life span of a system is 15 years. However, there are plenty of 25+ year old systems in operation.

Topics: Purified Water Systems

The Importance Of Quality Servicing And Calibration In The Successful Operation Of A Water Treatment System

You cannot beat quality servicing and calibration in the successful operation of water treatment systems.

Preventive Maintenance

Quality preventive maintenance procedures conducted by an experienced Engineer will optimise the performance of the plant and itemise and predict items that will require replacement in the future. During the servicing of a plant the full automatic process operation of the plant should be tested and replicated in detail. This will often involve adjustments to compensate for seasonal variations and temperatures. All flows, pressures, draws and velocities should be examined and compared with previous service and commissioning data. Quality preventive maintenance will maximise efficient plant operation and minimise costly plant down time.

Topics: Purified Water Systems, Servicing

Threats To Your Industrial Water Treatment System You Weren’t Aware Of

Meeting the BP, EP and FDA standards for the water used in your facility can seem fairly straightforward. However, there are many dangers lurking in and around your system that may be threatening the quality of your water, as well as the efficiency of your water system itself.

We are a specialist independent company involved in water purification and water treatment technologies

We are a specialist independent company involved in water purification and water treatment technologies